Samples of the reservoir fluid are usually collected at an early stage in the well’s producing life and dispatched to a laboratory for the f PVT analysis. The objectives of sampling are to receive samples from a suitable place in the production wells or surface facilities. The samples should represent the system in the reservoir under its initial conditions in order to determine its type, volumetric and phase behavior, and its composition. PVT analysis results are needed for geological and reservoir engineering evaluation and forecasting, as well as for laboratory studies concerning enhanced oil recovery (EOR).

There are basically three ways of collecting fluids samples from a well, either by Downhole Sampling, Wellhead Sampling or by Surface Recombination Sampling.

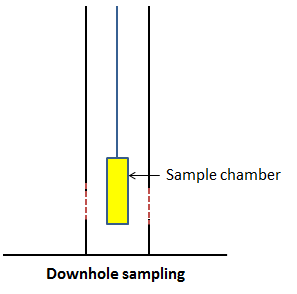

Downhole Sampling:

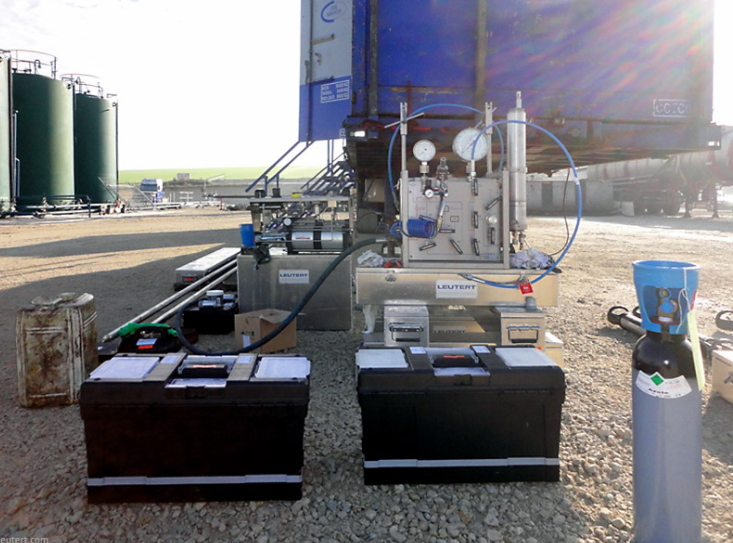

As illustrated by the following figure, this is the more direct method of sampling:

Bottom hole samplers are specially designed devices containing one valve or two valves at their extreme ends. They are run in the hole, on wireline, to the reservoir depth and the sample collected from the subsurface well stream at the prevailing bottom hole pressure. The valves are either mechanically or electrically operated to be close and trap a volume of the borehole fluids in the sampling chamber.

Once at the surface, the sample should immediately be transferred to containers through a flexible steel tube. This steel tube is filled up with an inert liquid, generally with mercury, together with the shipping bottle. This can be done using a mercury injection pump.

Subsurface sampling method will obviously yield a representative fluid sample of the reservoir giving that the oil is undersaturated with gas to such a degree that the bottom hole flowing pressure Pwf at which the sample is collected, is above the bubble point pressure.

- If the reservoir was initially at bubble point pressure Pb or suspected of being so, the subsurface sample should then be collected with the well still closed in.

- If the reservoir is known to be initially undersaturated the sample can be collected with the well flowing at a very low rate so that the Pwf is still above Pb.

Wellhead Sampling:

Sampling at the wellhead is a suitable process in case of the production of dry gas or undersaturated oil at wellhead conditions (wellhead pressure is greater than bubble point pressure). The container is connected with a valve at the wellhead and flushed with the fluid produced, the same procedure described in the previous method.

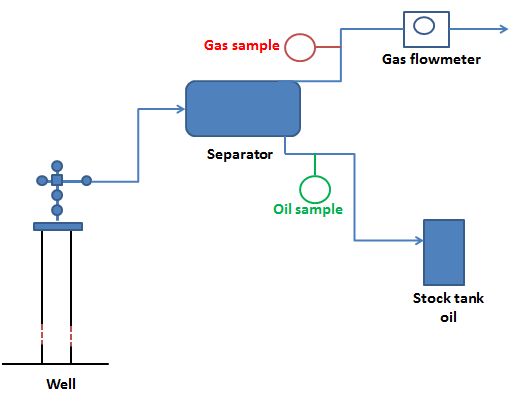

Surface Recombination Sampling:

Surface recombination sampling method is illustrated by the following figure; separate volumes of oil and gas are taken at separator conditions and recombined to give a composite fluid sample.

Before taking the sample, the well to be producing at a constant rate for several hours and the Gas Oil Ratio (producing GOR) is measured in scf of gas at separator pressure and temperature conditions. If the producing GOR is steady during the period of measurement then one can feel confident that recombining the oil and gas in the same ratio will yield a representative composite sample of the reservoir fluid.

In fact, a slight adjustment must be made to determine the actual ratio in which the samples should be recombined. This is because the oil sample is collected at separator pressure and temperature whereas the gas oil ratio is measured relative to the stock tank barrel. The measured GOR must be multiplied by the shrinkage factor from separator to stock tank conditions. This factor is usually determined in the laboratory as the first stage of a PVT analysis of a surface recombination sample by placing a small volume of the oil sample in a cell at the appropriate separator conditions and discharging it (flash expansion) to a second cell maintained at the field stock tank conditions.

[required GOR] = [measured GOR] × [shrinkage factor]

[GOR (scf/sep.bbl)] = [GOR (scf/stb)] × [GOR (stb/sep.bbl)]

Selection of wells for sampling:

To sample a representative oil and gas fluids, sampling has not to be taken from wells which are perforated at the water/oil or gas/oil contact and are producing water and/or non-equilibrium gas. The number of samples will depend on the dip of the structure as well as on the pay thickness.

References:

Fundamentals of Reservoir Engineering, Dake

Reservoir Fluids Properties, Heinemann