Tubing is a relatively small-diameter pipe that is run into a well to serve as a conduit for the passage of oil and gas to the field surface facilities for processing. Tubing must be adequately strong to resist loads and deformations associated with production and workovers. Further, tubing must be sized to support the expected rates of production of oil and gas.

Tubing Specifications:

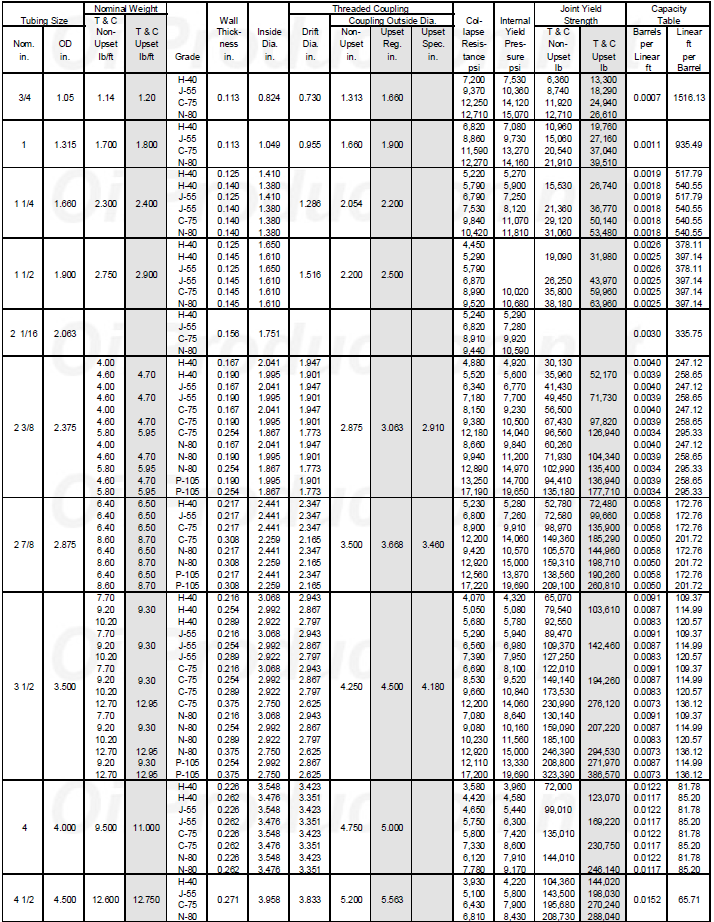

Tubing is specified by grade, outer diameter, weight, and connection. API tubing grades correspond to casing grades with the exception that P grade tubing has a tensile strength of 105,000 psi and is referred to as P105.

Tubing comes with non-upset (NUE) and external upset (EUE) ends. EUE tubing is more common, because of the benefit that cutting threads into the tubing ends does not reduce the body strength.

NB: for ESP applications, if power cable clearance between the tubing and casing becomes an issue, NUE tubing should be considered.

Internal diameter (ID): is a result of the OD and the wall thickness, and it is used to calculate pressure losses and velocities.

The drift diameter: is the diameter of a 42” long mandrel that passes through tubing joint. It is a foremost parameter as it gives the maximum OD of any equipment to run through the tubing string.

Maximum outside diameter: it depends on the nominal diameter and the connection type. It is critical as it determines the strings size that we can run in a given casing.

Nominal size: is the outside diameter of the pipe body. The most used sizes are: 2-⅜”, 2-⅞”, 3-½” and 4-½”.

The tubing joint length: is the length of tubing joint including the coupling and excluding the pin thread. It is classified into two length range: range I: from 20 ft to 24 ft (6.1 to 7.32 m) long, or range II: from 28 ft to 32 ft (8.53 to 9.75 m) long. The length range must be chosen with care. It must be compatible with the hoisting and storage capacity of the mast of the rig used when running in hole the equipment during completion as well as later on during workover operations.

Nominal weight: is the average linear weight of the tubing, connection included. It is expressed in lb/ft. It determines the tubing wall thickness. The most common nominal weights are:

- 6# and 4.7# for 2-⅜”

- 4# and 6.5# for 2-⅞”

- 2# and 9.3# for 3-½”

- 6# and 12.75# for 4-½”

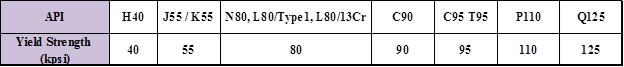

Steel grade: there are mainly two different types of steel used to manufacture tubing:

- API standard steels and grades for tubing: J55, C75, L80, N80, C90 and P105. The letter is a characteristic of the chemical composition and sometimes the thermal treatment. The number following the letter is the minimum body yield stress in 1000 psi and it is the minimum body yield stress guaranteed by the manufacturer.b

API standard as per API Spec 5 CT:

- Stainless steel, alloys, and special pipe:

When carbon dioxide and/or hydrogen sulfide are part of the produced fluids, it could necessary to use stainless steel, alloys, and special pipe. For example:

- 9 Cr is used for H2S applications.

- 13 Cr for CO2: 13% chromium is selected when there is no H2S in addition to the CO2.

- 22 Cr for CO2 + H2S: 22-25% chromium steel when the H2S partial pressure is not too high (some psi)

Connection, threads:

Tubings are screwed together through connections, which could be:

- by means of integral joint, the most common type of connection on small diameter pipe:

- by using a coupling (the most common connection), a collar with internal threads used to join two sections of threaded pipe.

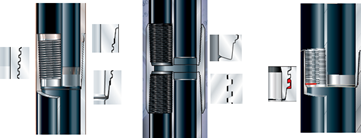

API tapered triangular threaded connections:

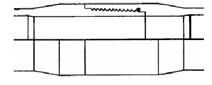

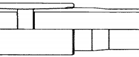

API proposes two types NUE & EUE coupling:

- with an increased wall thickness and diameter (called Upset) giving better tensile strength. It is called an External Upset End (EUE):

- No increase in diameter at the end of the pipe body, It is a called Non-Upset End (NUE):

API threads have a taper of 6.25% and 8 to 10 threads per inch. They are triangular and rounded on top. The seal is made by grease trapped between the threads, which is sufficient for low-pressure oil wells.

NB: In addition to providing the seal for the connection, grease is used to lubricate the threads and protect them from corrosion.

Premium connections:

For premium connections, the seal is made by a metal to metal shoulder (e.g. VAM joint and Hydril joint), and sometimes by an elastomer or Teflon joint. Premium connections are preferred for gas wells, high-pressure wells, as well as for wells producing corrosive effluents.

Mechanical characteristics of tubing pipe:

The pipe run into the well is subjected to variable pressures and temperatures in addition to its own weight, and these will create variations in stress. The main mechanical characteristics of tubing pipe are:

- Tensile strength: the greatest longitudinal stress that a metal can bear without tearing apart.

- Collapse pressure: expressed in psi or MPa, it is the minimum differential pressure applied from outside, that the tubing withstand without permanent deformation.

- Burst pressure or internal yield pressure: is the internal differential pressure that will cause a tubing to fail.

Special tubing:

Special tubings (e.g. fiberglass tubings and internally coated tubings) are used to meet the particular corrosion resistance requirements due to the presence of hydrogen sulfide or carbon dioxide and water.

- Fiberglass tubing: it is used in low pressure, shallow wells and as a tailpipe below the squeeze packer or for setting cement plugs. They are corrosion resistant and easily drillable.

- Internally coated tubing: for highly corrosive effluent. The coating is damaged mechanically by tools run inside the production string.

Standards for Tubulars:

API and ISO standards for Tubulars are detailed in the article titled “Updated list of API and ISO Standards for Tubulars”.

Reference