Tubings are screwed together through connections, which could either be:

- By means of integral joint (the most common type of connection on small diameter pipe),

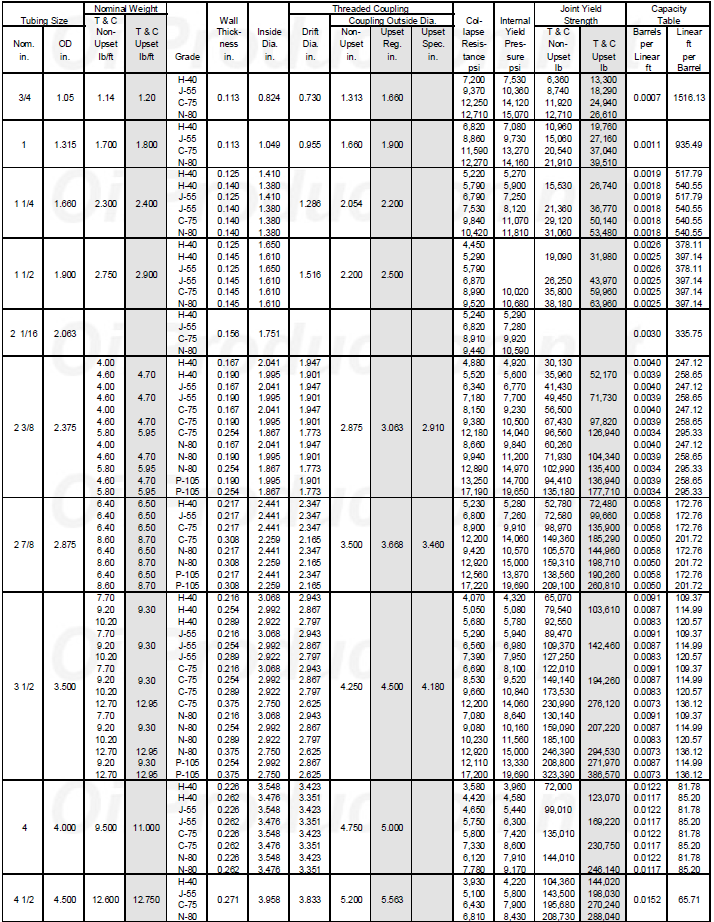

- Or by using a coupling (the most common connection); a collar with internal threads used to join two sections of threaded pipe.

Selection of tubing connections:

The type of tubing connections selected for a completion will depend mainly on the well characteristics. The connection must be able to contain the produced fluids safely and at the maximum pressures anticipated.

The basic requirements of a tubing string connection are:

- Strength compatible with the operational requirements of the string during, and after running;

- Sealing properties suitable for the fluid and pressures expected;

- Ease of stabbing during make-up, and safe breakout when pulling the tubing;

- Resistance to damage, corrosion, and erosion.

Types of thread connection:

There are two types of thread connection: API and Premium.