Tubings are screwed together through connections, which could either be:

- By means of integral joint (the most common type of connection on small diameter pipe),

- Or by using a coupling (the most common connection); a collar with internal threads used to join two sections of threaded pipe.

Selection of tubing connections:

The type of tubing connections selected for a completion will depend mainly on the well characteristics. The connection must be able to contain the produced fluids safely and at the maximum pressures anticipated.

The basic requirements of a tubing string connection are:

- Strength compatible with the operational requirements of the string during, and after running;

- Sealing properties suitable for the fluid and pressures expected;

- Ease of stabbing during make-up, and safe breakout when pulling the tubing;

- Resistance to damage, corrosion, and erosion.

Types of thread connection:

There are two types of thread connection: API and Premium.

- API connections:

API proposes two types of coupling: Non-Upset coupling (NU) and External Upset coupling (EU):

External Upset coupling (EU): with an increased wall thickness and diameter (called Upset) giving better tensile strength. It is called External Upset End (EUE).

Non-Upset coupling (NU): no increase in diameter at the end of the pipe body, It is a called Non-Upset End (NUE).

API threads have a taper of 6.25% and 8 to 10 threads per inch. They are triangular and rounded on top. The seal is made by grease trapped between the threads, which is sufficient for low-pressure oil wells.

API connections are perfectly well adapted and sufficient for most oil wells.

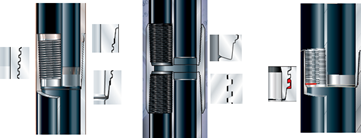

- Premium connections:

Premium connections are proprietary connections that offer premium features not available on API connections. Most offer a metal-to-metal seal (e.g. VAM joint and Hydril joint) for improved high pressure seal integrity. Premium connections exist with features such as flush connections, recess free bores, and special clearance. This type of connection is preferred for gas wells, high-pressure wells, as well as for wells producing corrosive effluents.

An example of a premium thread is shown in the following Figure.

References:

- Well Completion and Servicing, D. Perrin (Editions Technip).

- Completion Design Review with Focus on Well Integrity and Productivity, Karianne Skårnes Vågenes, Norwegian University of Science and Technology https://brage.bibsys.no/xmlui/handle/11250/239878