In this article, the major reference guides for Well Integrity are presented. These guides can be considered as reference documents as well as a basis for training classes on the subject of Well Integrity.

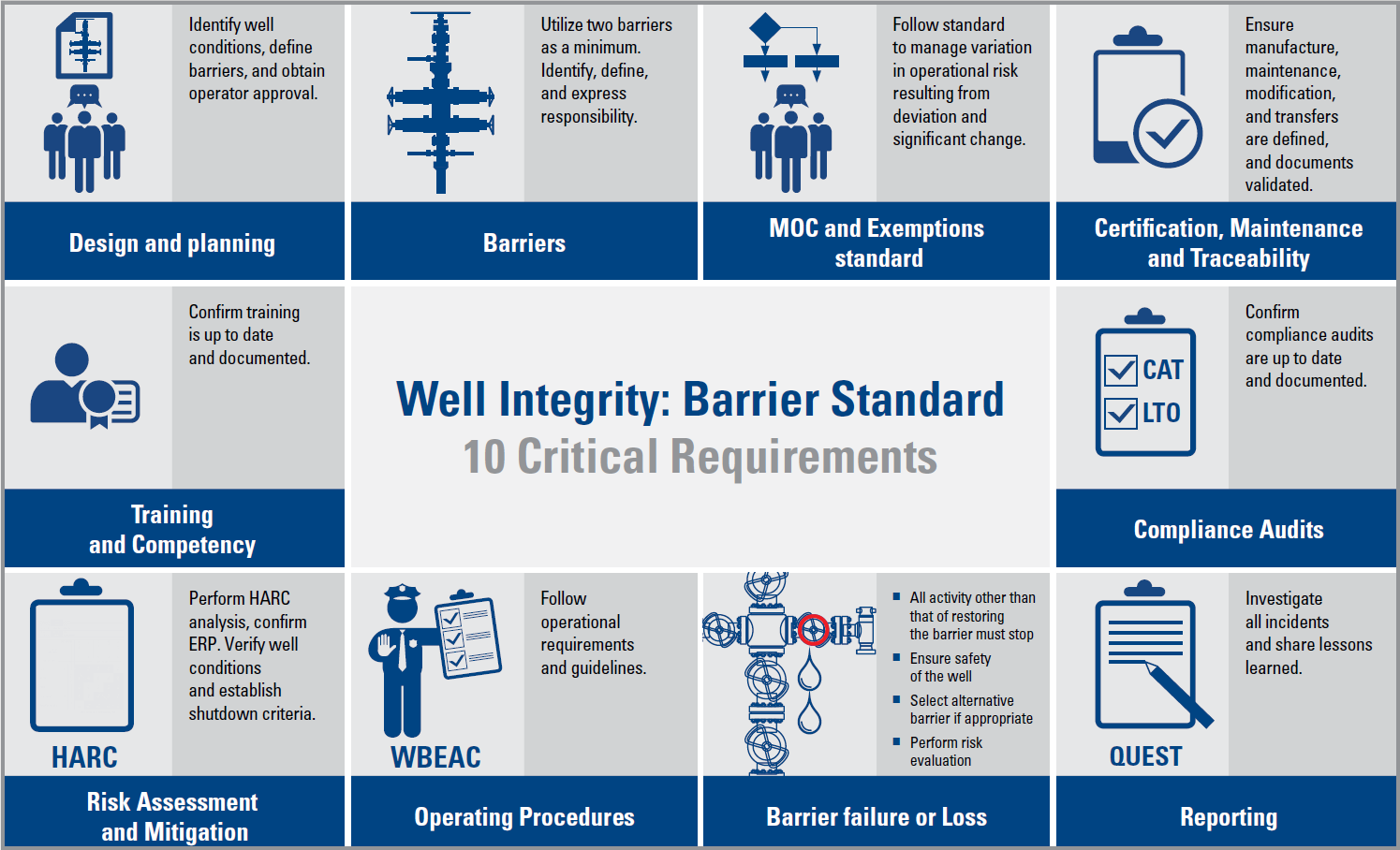

The standard defines the minimum functional and performance oriented requirements and guidelines for well design, planning and execution of safe well operations. The focal of the standard is well integrity.

Well integrity is defined to be “application of technical, operational and organizational solutions to reduce risk of uncontrolled release of formation fluids throughout the life cycle of a well”. The standard focuses on establishing well barriers by use of WBE’s (well barrier elements), their acceptance criteria, their use and monitoring of integrity during their life cycle. The standard also covers well integrity management and personnel competence requirements. The standard does not contain any well or rig equipment specifications.”

The following video explains the basics of Cement Bond Log:

The following video explains the basics of Cement Bond Log: