The Cement Bond Logging tools have become the standard method of evaluating cement jobs. They indicate how good the cement bond is. A cement bond log (CBL) documents an evaluation of the integrity of cement job performed on an oil well. It is basically a sonic tool which is run on wireline. Similar to a ringing bell, when no cement is bonded to the casing, pipe is free to vibrate (loud sound). When the casing is bonded to hard cement, casing vibrations are attenuated proportionally to bonded surface.

CBL Measurement Principle:

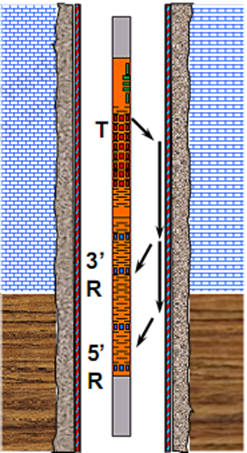

The basic tool configuration of CBL-VDL log is composed by One Transmitter and Two Receivers: the first Receiver is located 3 ft. from the Transmitter and is used for CBL Measurement. The second Receiver is located 5 ft. from the Transmitter and is used for Variable Density Log (VDL).

NB: CBL-VDL logging tools MUST be centralized.

The following video explains the basics of Cement Bond Log:

The following video explains the basics of Cement Bond Log:

NB: API 10TR-1 is an API standard for Cement Sheath Evaluation.

CBL-VDL Log Applications:

Operator needs to evaluate cement job by checking the integrity of cement and verifying zone isolation. Also, CBL-VDL log is used to determine cement quality and answer the following questions:

- Is there any channeling?

- Is it necessary to Repair? And, will it be possible to repair (by performing a cement/chemical squeeze)?

CBL Qualitative Interpretation:

| Condition | Transit Time* | CBL Amplitude | VDL |

| Free Pipe | Normal | High | · Casing arrivals,

· Usually No formation arrivals |

| Good bond to casing and formation | Normal to High/Noisy | Low | · No casing arrivals,

· Formation arrivals |

| Good bond to casing NOT to formation | Normal to High / can be Noisy | Low | · No casing arrivals,

· No formation arrivals |

| Poor bond to casing | Normal | Medium to high | · Strong casing arrivals,

· No formation arrivals |

| Micro-annulus | Normal | Medium to high | · Casing arrivals,

· Formation arrivals |

| Channeling | Normal | Medium to high | · Casing arrivals,

· Formation arrivals |

| Eccentered Tool | Low | Low | · It depends! |

* Transit time is explained in the previous video.

CBL Operations Requirements:

As per API 10TR-1 “Cement Sheath Evaluation”, the following recommended practices are required to produce a valid CBL:

- A fluid-filled borehole. Gas or air bubbles will induce inaccurate readings.

- Centralized CBL tool during the run.

- A bit and scraper run is recommended to remove cement and/or scale from the casing wall.

- Wellbore schematic.

- Plot of the cement strength vs. time to determine the time after which logging can produce a valid log.

- Predicted cement tops for the lead and tail cements.

- Casing and centralizer report to determine where casing eccentering may occur.

- Openhole logs with a caliper and lithology.

- An understanding of fluid type or gas in the formation pore space.

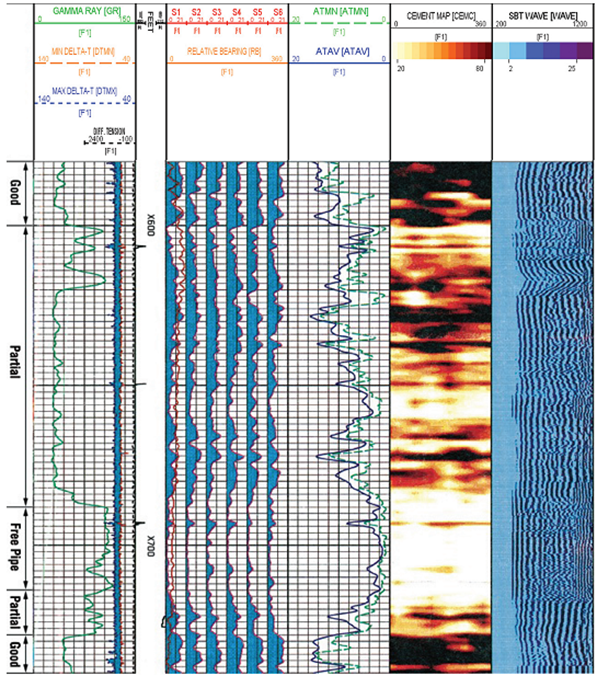

Radial-CBL:

Radial-CBL tools were developed to overcome some limitations of conventional CBL tools and to permit more accurate evaluation of cement distribution by providing the precise location of partial bond and channeling. These tools use one or more azimuthally sensitive transducers to evaluate cement quality around the circumference of the casing. Data from these tools are presented as individual log curves or as azimuthal images (“maps”) of cement quality generated by interpolating between the individual azimuthal measurements. In addition, each tool design also provides a conventional 5-ft VDL waveform measurement to provide information about the cement to formation bond.