Tubing is a relatively small-diameter pipe that is run into a well to serve as a conduit for the passage of oil and gas to the field surface facilities for processing. Tubing must be adequately strong to resist loads and deformations associated with production and workovers. Further, tubing must be sized to support the expected rates of production of oil and gas.

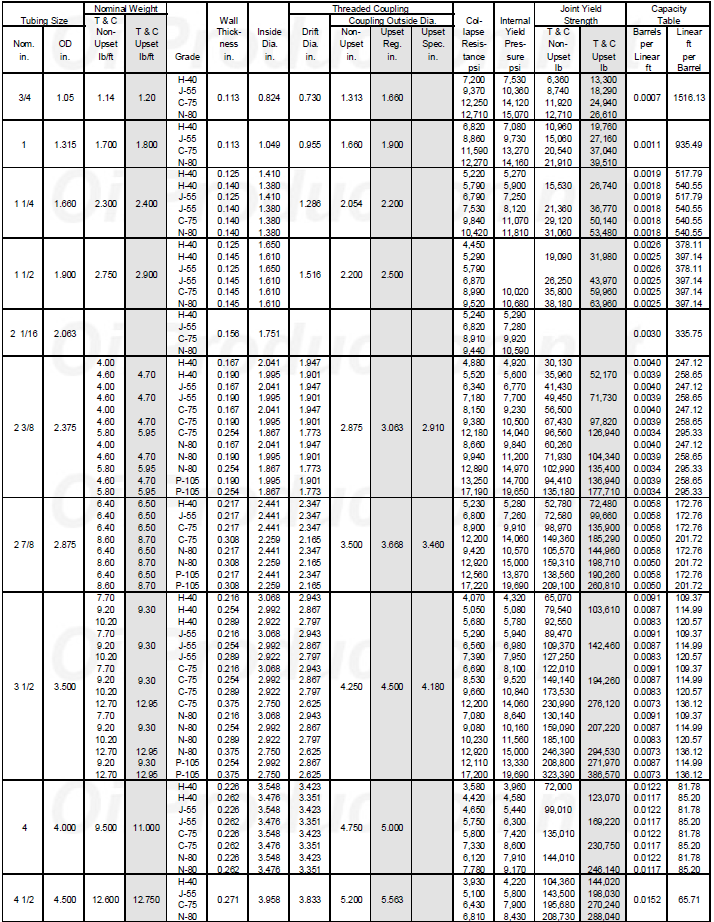

Tubing Specifications:

Tubing is specified by grade, outer diameter, weight, and connection. API tubing grades correspond to casing grades with the exception that P grade tubing has a tensile strength of 105,000 psi and is referred to as P105.