When there is a catastrophic pumping unit failure it is natural to wonder what happened and how this failure could have been prevented. However, the right answer may or may not be simple to find. The following list shows the most common reasons for a failure and how to prevent or minimize its occurrence in the future:

Continue readingTag Archives: beam pump

Sucker Rod Pumping Speed Calculation

Sucker-rod pumping units can be operated over a range of pumping speeds. It is expressed in Strokes per Minute (SPM). Obviously, this assumed that the up and down stroke of a unit forms one complete stroke cycle.

Sucker rod pumping speed can be calculated manually using a stopwatch or automatically by the mean of a pump-off controller (POC). This article will detail the manually pumping speed calculation procedure.

Manually Pumping Speed Calculation Procedure:

- Start the stopwatch at the bottom of the stroke and measure the time it takes for the unit to complete 10 strokes.

- Stop the stopwatch at the end of the 10 strokes when the PU is back at the bottom of the stroke. Make a note of the number of seconds it took.

- Convert the number of seconds into minutes (divide by 60).

- Divide 10 (the number of strokes) by the time in minutes to obtain the pumping speed expressed in strokes per minute (SPM).

Exercise: Calculate the pumping speed of this PU.

Beam Pump Artificial Lift Optimization

This article gives you some good practices and rules of thumb for optimizing beam pump applications. The following topics have been presented:

- Artificial Lift Optimization – What does it mean?

- Required information

- Typical design situations

- Optimization considerations

- Simulate / Measure initial conditions

- Pump condition, structure loading, and gearbox Loading

- Miscellaneous notes

- Design Guidelines: Pump Efficiency, Structure Loading, Gearbox Loading

- Case 1: Increase Capacity

- Case 2: Size unit for well w/no unit

- Dialing in your design

- Unit Sizing “Rules of Thumb”

- Sucker Rod Design

- Rod Guides: Snap Ons, Molded Guides

Why Do We Counterbalance Sucker Rod Pumping Units?

A good understanding of counterbalance is vital to the successful operation of surface sucker rod pumping units. Poor counterbalance practices can cause early failure of the gear reducer gearing and will result in excessive energy cost.

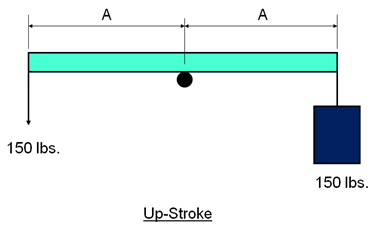

Non-counterbalanced lever system:

The up-stroke:

The figure above represents a simple non-counterbalanced lever system. On the up-stroke, by pulling down on the end of a beam, a man is lifting a bucket full of water having a combined weight of 150 lbs.

Note that the upstroke effort of the man is a substantial 150 lbs.

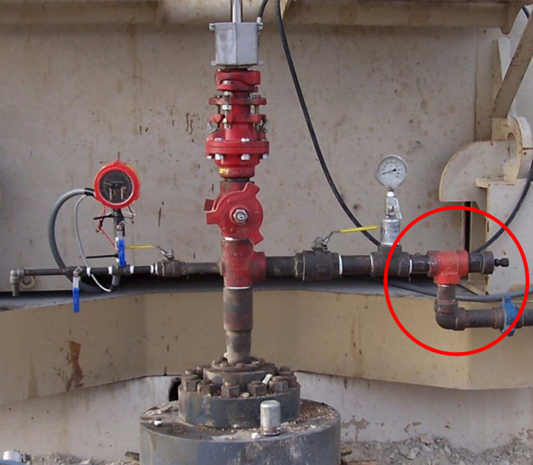

Back Pressure Regulators for Gassy Sucker Rod Lifted Wells

The problem of heading (flow off and pump) is often encountered in gassy wells. This heading effect which can blow the tubing dry occurs as follows:

- Gas expansion in the tubing as oil from the reservoir travels towards the surface (due to gas pressure decrease).

- Formation of a gas “plunger” that can push the liquid above it out of the tubing and into the flow line at high speed. As the gas forces the liquids out of the tubing, the pressure in the tubing decreases rapidly and the gas expands even more.

- This heading behavior of reservoir fluids causes cycles of high production followed by low or no production.

When heading process starts, the expanding gas pushes the liquid into the flowlines and increases production for a short time. In the meantime, the liquid leaving the tubing is replaced by more and more free gas. Eventually, the tubing is blown dry and production stops until the tubing fills with liquid again.