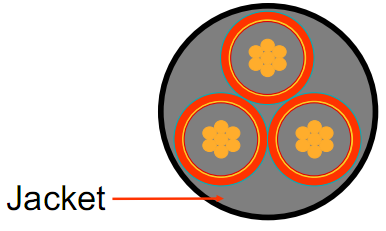

As per API RP11S5, cable jackets are protective coverings used to mechanically shield the insulation from the downhole environment. The jacket materials protect the insulation from mechanical abuse associated with handling. Some jacketing material may provide secondary insulation. The most used types of jackets in submersible pump cable are made of: EPDM elastomers or nitrile.

As for the other parts of submersible power cable, jacket selection depends on many factors mainly related to produced fluids properties and well behavior; such as: the downhole temperature and well conditions.

When selecting the cable jacket the following rule of thumbs could help in the selection of the suitable cable which fit the well properties:

- The EPDM jacket operates at higher temperature than the nitrile jacket, but the nitrile is tougher and more oil resistant. Nevertheless, oil swell resistance of EPDM jacket can be reduced by proper formulation.

- EPDM is inherently better than nitrile for handling and installation at lower surface temperatures.

- The rated temperature of the cable is limited by the temperature of the jacket material. EPDM has an approximate limit of 204 C / 400 F, while nitrile is limited to 140 C / 284 F.

To maximize the life of cable jacket, causes of embrittlement (age hardening) have to be avoided. In addition to handling and downhole temperatures, jacket degradation is caused by pressure cycling and exposure to downhole chemicals, gas type and gas concentration (especially: sour gases).

Finally, armor and / or constraining layers are critical to the protection of the jacket.

Reference:

API Recommended Practice 11S5 (RP 11S) – First edition, February 1, 1993.