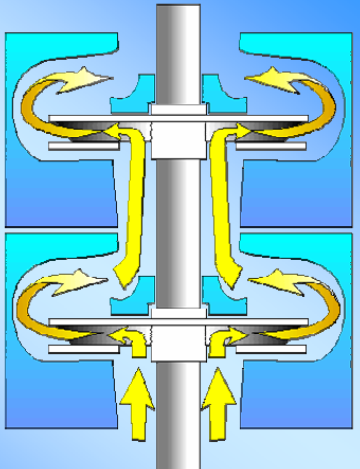

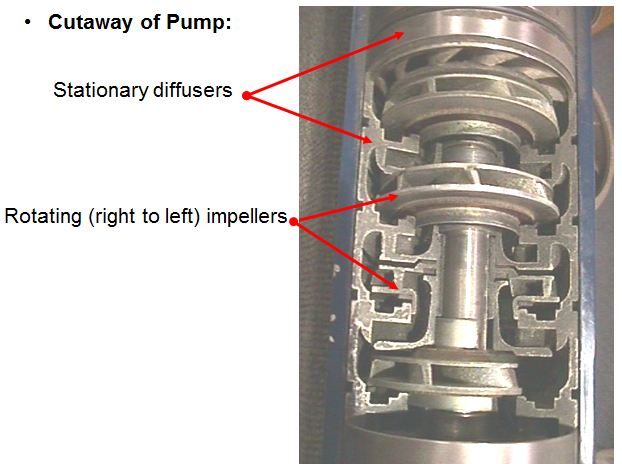

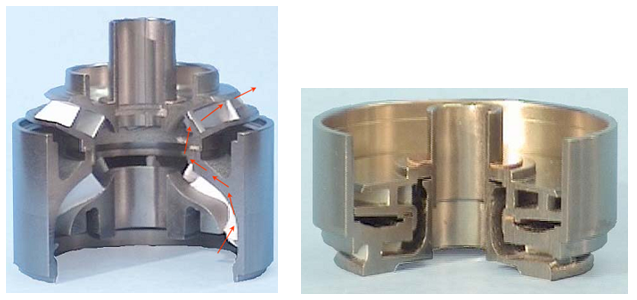

A “ Pump Stage ” consists of an impeller, diffuser and thrust washers. As shown by the following figure, the impellers rotate with the shaft and spin at the RPM of the motor. The stationary diffusers turn the fluid into the next impeller and do not rotate. Pumps are assembled by stacking stages on a shaft and compressing the stack in a housing. A stage will produce a given amount of flow and lift (head) at the motor RPM.