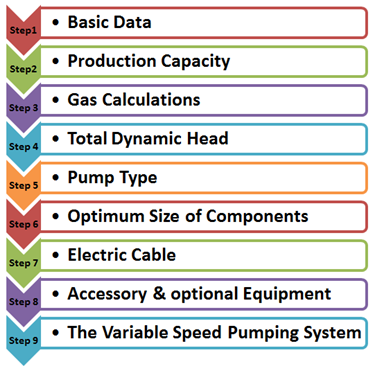

Centrilift has established a nine-step procedure to design the appropriate electrical submersible pump in order to have an efficient and cost-effective performance. This article gives an overview of the ESP nine step design procedure and outlines the procedure as a manual process to illustrate the design steps. Each of the nine steps will be explained in detail in the next articles.

- Step 1: Basic Data

- Step 2: Production Capacity

- Step 3: Gas Calculations

- Step 4: Total Dynamic Head

- Step 5: Pump Type

- Step 6: Optimum Size of Components

- Step 7: Electric Cable

- Step 8: Accessory & optional Equipment

- Step 9: The Variable Speed Pumping System

Specific examples will be worked through in each step of the ESP design.

This nine step procedure is a basic hand-design of simple water and light crude oil. For more complicated well conditions, such as high GOR, viscous oil, high-temperature wells, there are many of available ESP design software (e.g. Prosper software – Product of Petroleum Expert; Pipesim software – Product of Schlumberger; Autograph PC software – Product of Baker Hughes; Solution Sizing Software – Product of General Electric; DesignRite Software – Product of Schlumberger). The fashion of use of each of these ESP design software will be presented and explained in detail in upcoming articles in our website.