Samples of the reservoir fluid are usually collected at an early stage in the well’s producing life and dispatched to a laboratory for the f PVT analysis. The objectives of sampling are to receive samples from a suitable place in the production wells or surface facilities. The samples should represent the system in the reservoir under its initial conditions in order to determine its type, volumetric and phase behavior, and its composition. PVT analysis results are needed for geological and reservoir engineering evaluation and forecasting, as well as for laboratory studies concerning enhanced oil recovery (EOR).

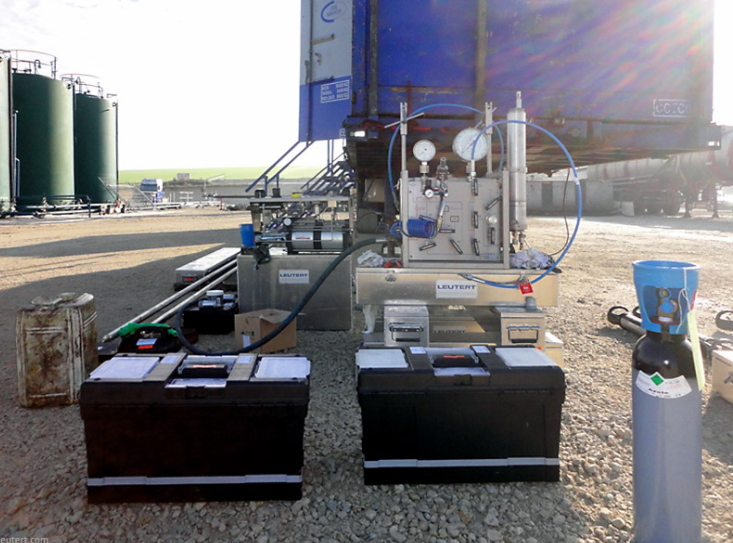

There are basically three ways of collecting fluids samples from a well, either by Downhole Sampling, Wellhead Sampling or by Surface Recombination Sampling.