According to Norsok D-010, well integrity is defined as the “application of technical, operational and organizational solutions to reduce the risk of uncontrolled release of formation fluids and well fluids throughout the life cycle of a well”.

Well Integrity is defined in ISO/TS 16530-2 as: “containment and the prevention of the escape of fluids (i.e. liquids or gases) to subterranean formations or surface”

In API RP 65-2, well integrity is defined as: “a quality or condition of a well being structurally sound with competent pressure seals by application of technical, operational, and organizational solutions that reduce the risk of uncontrolled release of formation fluids throughout the well life cycle “.

Following from the aforementioned definitions of well integrity, the personnel planning the drilling and completion of wells will have to identify the solutions that give safe well life cycle designs that meet the minimum requirements of the standard.

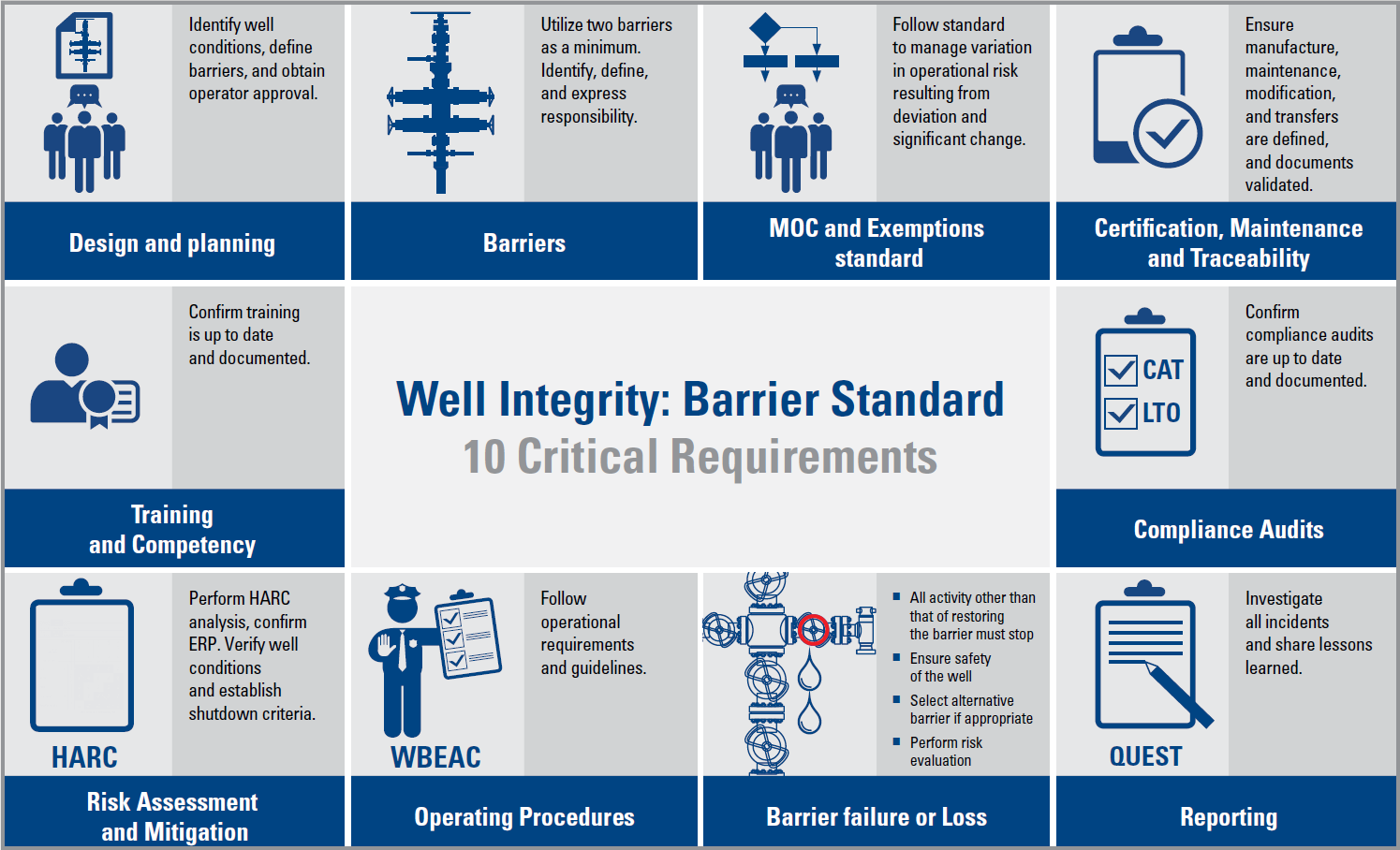

Well Integrity: 10 Critical Requirements

1. Design and planning:

Identify well conditions, define barriers, and obtain operator approval.

2. Barriers:

Utilize two barriers as a minimum, identify, define, and express responsibility.

3. Management of Change (MOC) and exemptions standard:

Follow standard to manage variation in operational risk resulting from deviation and significant change.

4. Certification, Maintenance, and traceability:

Ensure manufacture, maintenance modification, all transfers are defined, and documents validated.

5. Compliance Audits:

Confirm compliance audits are up to date and documented.

6. Reporting:

Investigate all incidents and share lessons learned.

7. Barrier failure or loss:

- All activity other than that of restoring the barrier must stop.

- Ensure safety of the well.

- Ensure alternative barrier if appropriate.

8. Operating Procedures:

Follow operational requirements and guidelines.

9. Risk Assessment and Mitigation:

Perform HARC analysis, confirm ERP, verify well condition and establish shutdown criteria.

10. Training and Competency:

Confirm training is up to date and documented.

For operating procedures I would prefer apply and follow standard SOP for wells integrity. Leaving the matter to OPCO’s or individual procedures might lead to failures. For example there are company use TRDP SSSV as a physical mechanical barrier and others are not. We need to be specific and clear in things related to people and asset safety.

Totally agree with you Mahmoud.