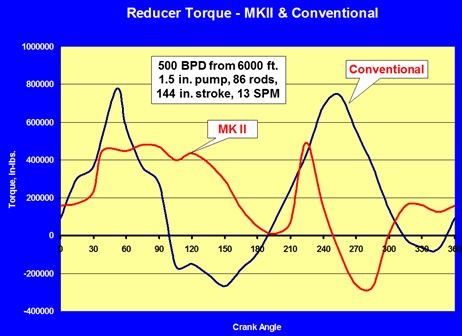

This article helps understand the difference between Conventional & Mark II pumping units in term of production performance. SROD, the predictive program from General Electric (GE), has been used in order to compare the Reducer Torque Performance, the Stroke Length, and the Polished Rod Velocity, of a conventional unit and a Mark II unit. In order to do that, production data from the well MF-1 are used.

MF-1 is an oil well activated using a sucker rod pump. The target rate is 500 BPD, the pump is set at 6000 ft, the plunger diameter is 1.5 inch, the rod string is 86, the stroke length is 144 inch and the pumping speed is 13 spm.

Reducer Torque:

- Reducer Torque vs. Crank Angle:

SROD, the predictive program from GE, has been used in order to compare the reducer torque performance of a conventional unit and a Mark II unit. The plots “Torque (in in-lbs) versus the crank angle” are depicted in the following graph.

Note that the MKII does a better job approaching the uniform torque goal than the conventional unit and therefore has lower peak torque.