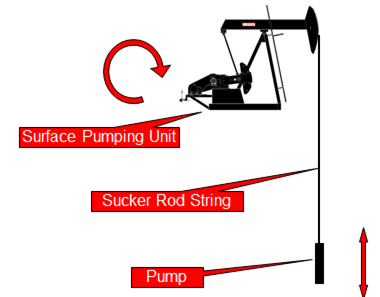

Rod Pumping System is a system of artificial lift using a surface pumping unit to impart reciprocating motion to a string of rods. Rod string then extends to a positive displacement pump placed in well near producing formation. In other words, the primary function of a rod pumping system is to convert the energy supplied at the prime mover into the reciprocating motion of the pumping unit required to transmit energy through the rod pumping to the downhole pump in order to artificially lift the reservoir.

Rod Pumping System:

The rod pumping system is made up of three components:

- The surface pumping unit: which provides the means of turning the rotating power and motion of the motor into the reciprocating motion at the correct speed needed at the pump.

- The rod string: that connects the surface unit to the pump and provides the force at the pump to lift the fluid to the surface.

- The pump: which pumps the fluid to the surface.

The integrity of this pumping system is only as good as each of the links or components.

Application Considerations:

| Typical Range | Maximum (Special Analysis Required) | |

| Operating Depth | 100 to 11,000 ft TVD | 16,000 ft TVD |

| Operating Volume | 5 to 1,500 BPD | 5,000 BPD |

| Operating Temperature | 100 to 350°F | 550°F |

| Wellbore Deviation | 0 to 20° Landed Pump | 0° to 90° Landed Pump. <15°/100 ft Build Angle |

| Corrosion Handling | Good to Excellent

With Upgraded Materials |

|

| Gas Handling | Fair to Good | |

| Solids Handling | Fair to Good | |

| Fluid Gravity | >8° API | |

| Servicing | Workover or Pulling Rig | |

| Prime Mover Type | Gas or Electric | |

| Offshore Application | Limited | |

| System Efficiency | 45 to 60% | |

Advantages and limitations:

| Advantages | Limitations |

|

|

It’s great that you’ve mentioned how one advantage of using rod lift products in a construction site is that it provides flexibility when it comes to pumping, as production can be adjusted depending on the length of the stoke and speed. My brother is interested to learn more about construction and I believe this includes the different equipment and how they are supposed to be used. I’ll share this with him so that he’ll know more about the rod lift as well as the advantages of using it.