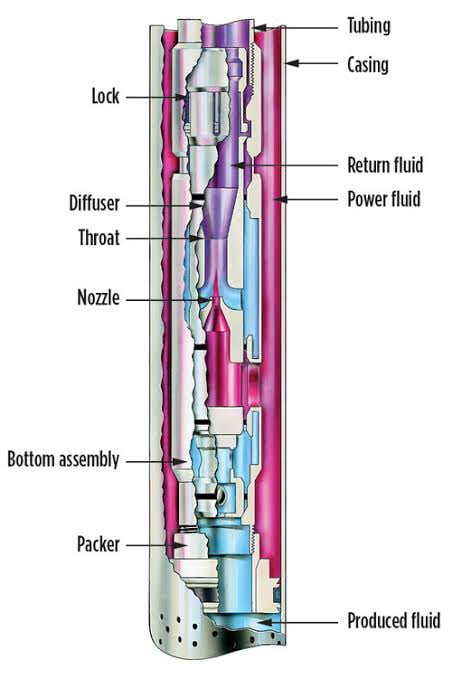

The jet pump operates by pumping power fluid at high pressure and rate from surface to activate/drive a downhole pump. Looking at the downhole jet pump, there are three main components:

- Nozzle,

- Throat,

- And Diffuser.

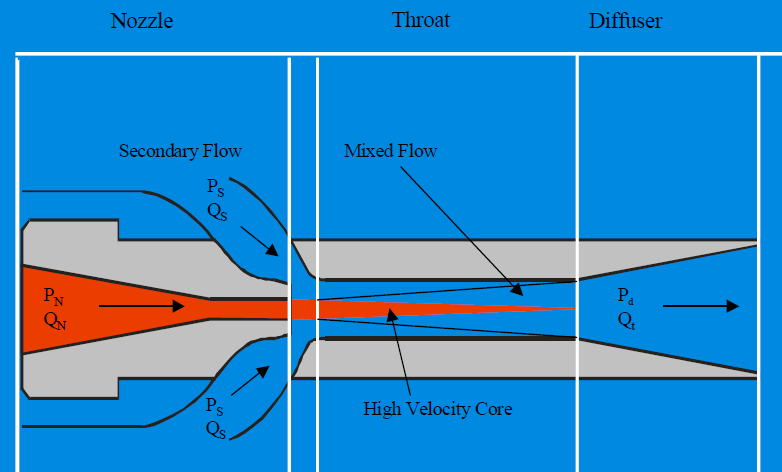

The nozzle and throat are the key components of a jet pump. The ratio of the areas of these two parts is known as the area ratio of the pump and it determines the performance characteristics of the pump. Pumps with the same area ratio have the same performance and efficiency curves

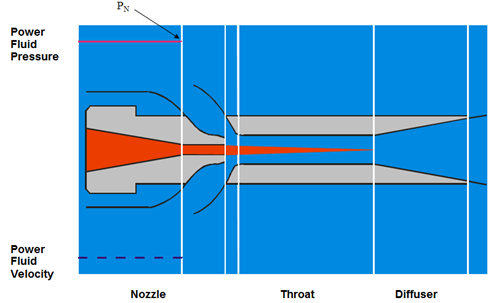

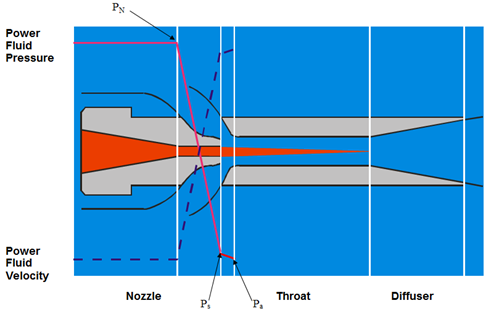

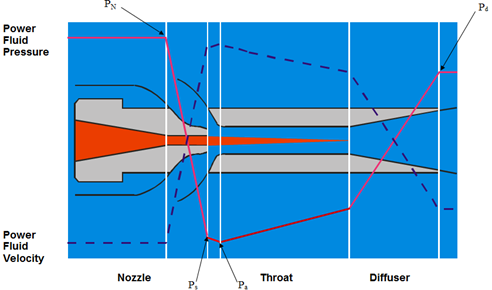

Jet Pumps operates on Venturi principle. Above the JP, before entering the nozzle, the power fluid has high pressure (designated as PN) and low flow velocity.

While the power fluid passes the nozzle, due to the decrease in flow area it is transformed from low velocity, high static pressure flow to a high velocity, low static pressure flow (PS). This creates a pressure drop below the nozzle which drives the reservoir fluids into the pump.

Inside the Throat, the power fluid mixes with reservoir fluids. This area must be able to pass the power fluid as well as the liquids and gas being produced. The area in the pump that must accommodate just the produced fluids (liquid and gas) is the annular area between the nozzle and the throat and it is this area that determines the cavitation characteristics of the pump.

Inside the Diffuser, due to increase in cross-sectional flow area the mixture (power fluid + reservoir fluid) flow velocity decelerates and gains pressure necessary to lift it to the surface.

The nozzle and throat are the key elements of downhole jet pumps. The performance capability of any jet pump depends upon the area ratio of these two parts. The volume of power fluid used will be mainly proportional to the size of the nozzle.

The article “Jet Pump Working Principle” details how the whole jet pumping system works.

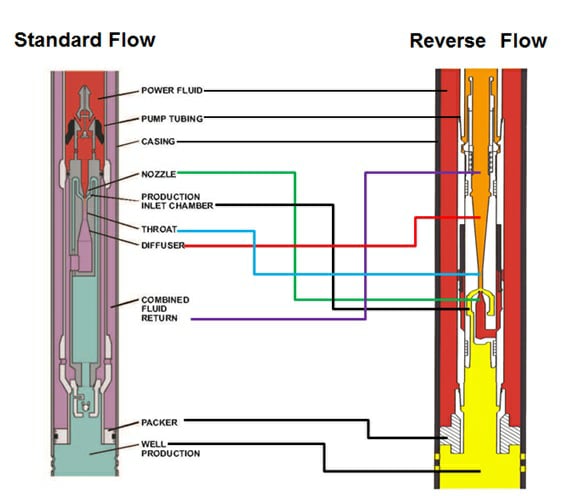

Standard Flow vs. Reverse Flow:

We generally talk about Standard Flow when the power fluid is injected into the tubing, and Reverse Flow when injected in the annular space. The following Figure shows both configurations:

Reference:

- First ever sub-sea hydraulic Jet Pump System used to optimize single well development offshore Tunisia.

This paper was presented at the 12th Offshore Mediterranean Conference and Exhibition in Ravenna, Italy, March 25-27, 2015.