The constant up-and-down movement of a sucker rod creates excessive friction between rods and tubing which can result in premature rod and tubing failures due to excessive wear. If left unchecked, this generally requires a costly intervention to make repairs.

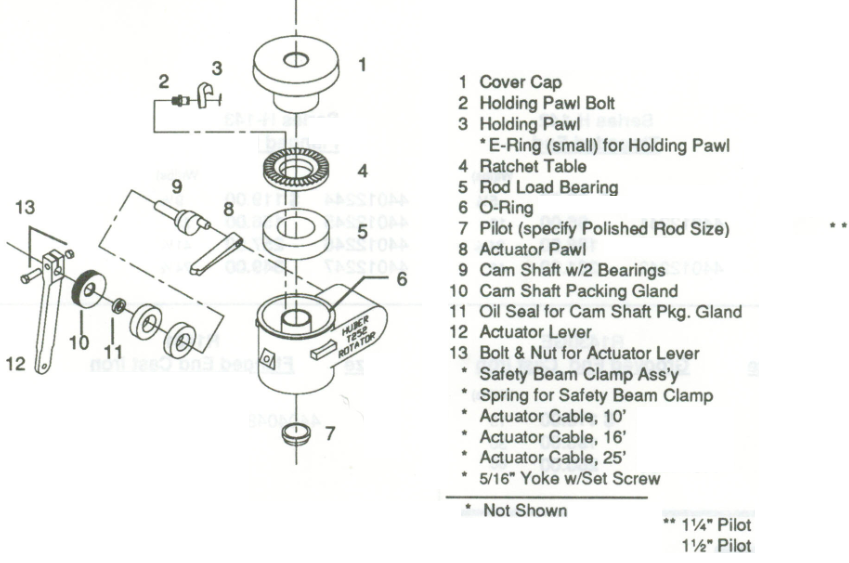

To extend the sucker rod run life, one of the widely used techniques is the use of rod rotators. A rod rotator is a mechanical device installed on the polished rod between the carrier and the polished rod clamp. It incrementally rotates the rod with each stroke. A rotating mechanism with an actuator lever arm is connected to the walking beam with a metal string. As the surface unit moves up and down, it pulls and releases this metal string so that, moves the actuator lever arm up and down. The rotation mechanism is activated and this slowly rotates the polished rod and the rod string below.

Rod string rotation distributes the frictional wear caused by the interference between the rod and the tubing. This more evenly spread the rod wear around the perimeter of the rods – rather than isolating this wear to just one spot – and helps maximize the run life of the rod string.

Furthermore, Rod rotation, used in conjunction with rod guides, is the most effective means of removing paraffin between rods and tubing.

Rod rotators need to be selected properly and are dependent on the well load. A rod rotator should not be used when rods can’t rotate freely. If the rods torque up, a backlash could cause the rods to unscrew.

Also, rod rotators are not recommended to be used with fiberglass rods. “As experimentally verified, the typical torque developed by rod rotators never reaches the critical allowed torque on the steel rods but, at the same time, may damage fiberglass rods” (Sucker-Rod Pumping Handbook, By Gabor Takacs).

A previously mentioned, rod rotator will allow rods to wear evenly all around, but tubing still wears in one location. In case of excessive wear on the tubing due to the friction between rods and tubing, tubing rotators could reduce the failure frequency. Refer to the article “Tubing Rotator reduces rod pumping failures” for more details.

The following video shows how to retrofit a rod rotator: