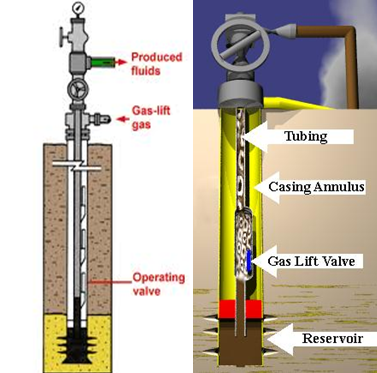

The operation of ”rocking” a gas-lift well, also called: ”fluid level depressing”, is required to unload the well when the fluid column is heavier than the available lift pressure. Thus, the top gas lift valve cannot be uncovered with the available injection-gas pressure.

”Rocking” the well consists on applying an injection gas pressure simultaneously to the tubing and casing. The injected gas in the tubing will push the fluid column back into the formation; therefore reduce height, thus the weight of the fluids being lifted and allow unloading with the available lift pressure.

The tubing pressure is released rapidly, and the source of the major portion of the fluid entering the tubing is load fluid from the annulus. This procedure may be required several times to lower the fluid level in the casing annulus below the depth of the top gas lift valve.

PS: Several hours may be required to ”rock” a well having low reservoir permeability.

”Rocking” Procedure:

The proper procedure for “rocking” the well follows:

- First, with the wing valve on the flowline closed, inject lift gas into the tubing until the casing and tubing pressures indicate that the gas lift valve has opened. A small copper tubing or flexible high-pressure line can be used for this purpose. When a valve opens, the casing pressure begins to decrease and to equalize with the tubing pressure. The tubing pressure also should begin to increase at a faster rate with injection gas entering the tubing through the valve and surface connection.

- Next, stop gas injection into the tubing and immediately open the wing valve to lift the liquid slug above the gas lift valve into the flowline as rapidly as possible. A flowline choke may be required to prevent venting injection gas through the separator relief valve. Some surface facilities are overloaded easily, and bleeding off the tubing must be controlled carefully.

PS: The presence of check valves inside unloading valves and orifice prevent fluids from being displaced back into the casing.

Remedial solutions if ”rocking” the well is not possible:

If the fluid used to kill the well can’t be injected in the formation while rocking (risk of causing reservoir and/or near wellbore damage), two solutions can be considered:

- Well swabbing: if applicable (no TRSV installed), the well can be “swabbed” to allow unloading to a deeper valve, however, the swabbing job should be well assessed/designed especially for well with high productivity. This job is performed using a slickline unit.

- Nitrogen Lift job: It is more safely than swabbing job, but much more expensive.

If the problem is severe, shooting an orifice into the tubing to achieve a new point of operation may be the only solution (if redesigning the well and working-over the well to respace Gas Lift Mandrels is not feasible).

Reference: Gas lift operations