This article gives you some good practices and rules of thumb for optimizing beam pump applications. The following topics have been presented:

- Artificial Lift Optimization – What does it mean?

- Required information

- Typical design situations

- Optimization considerations

- Simulate / Measure initial conditions

- Pump condition, structure loading, and gearbox Loading

- Miscellaneous notes

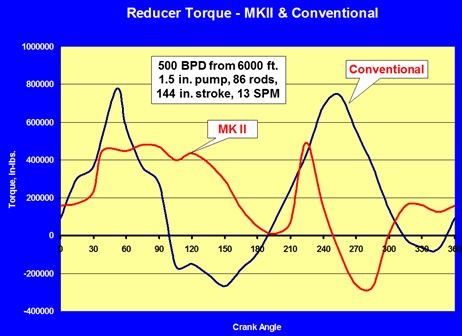

- Design Guidelines: Pump Efficiency, Structure Loading, Gearbox Loading

- Case 1: Increase Capacity

- Case 2: Size unit for well w/no unit

- Dialing in your design

- Unit Sizing “Rules of Thumb”

- Sucker Rod Design

- Rod Guides: Snap Ons, Molded Guides