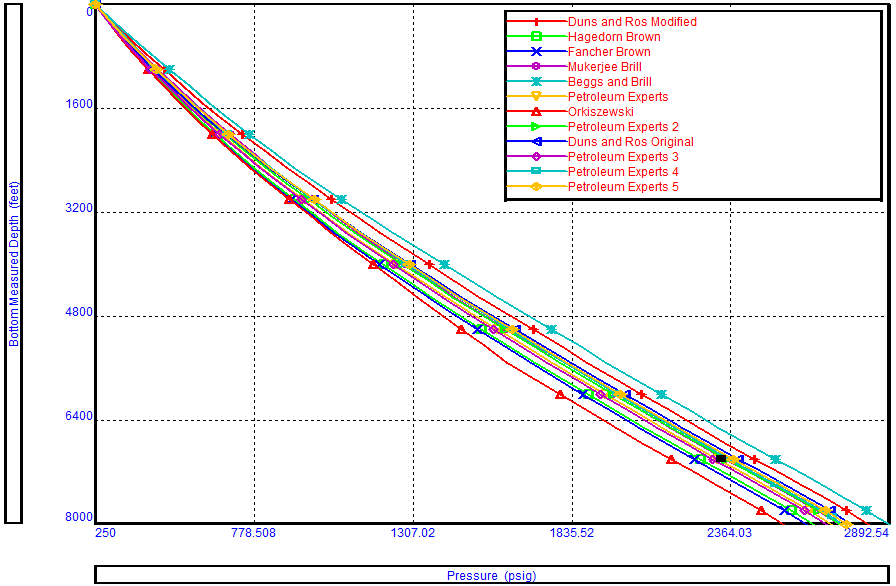

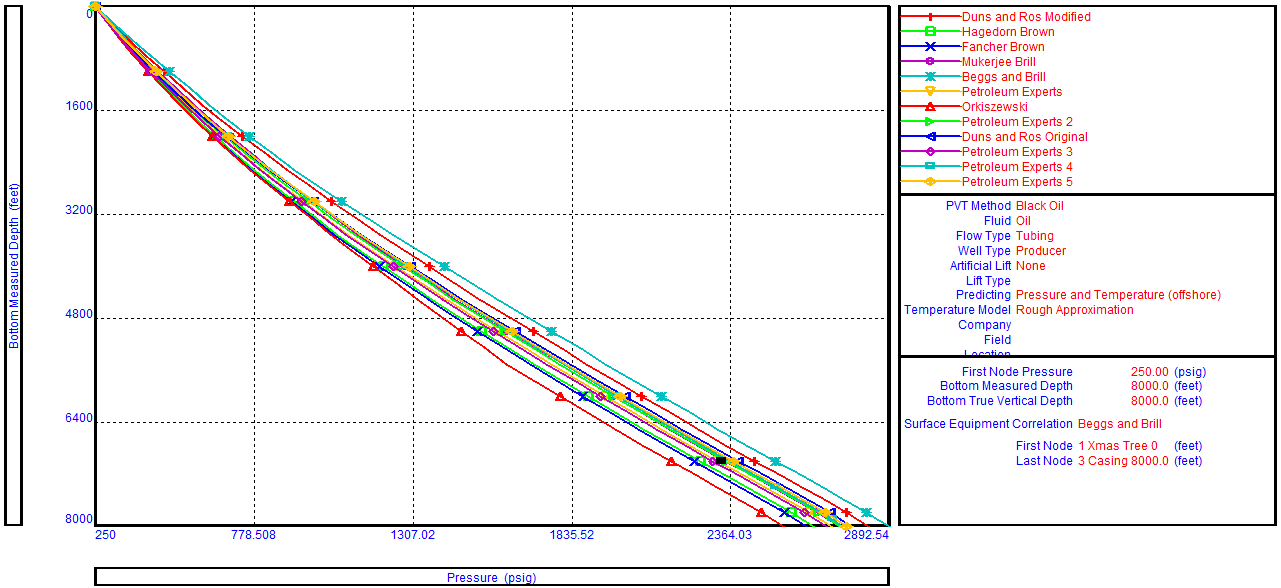

Multiphase correlations References:

| n° | Correlation | Description | Reference |

| 1 | Anand, et al | Predicting Thermal Conductivities of Formations from Other Known Properties. | JPT (Oct. 1980). |

| 2 | Ashford, F.E, & Pierce, P.E. | The Determination of Multiphase Pressure Drops and Flow Capacities in Downhole Safety Valves (Storm Chokes). | SPE 5161 1974 SPE Annual Fall Meeting, Houston Oct. 6-9. |

| 3 | Beggs, H.D. & Brill, J.P. | A Study of Two Phase Flow in Inclined Pipe. | JPT (May 1973), 606-617. |

| 4 | Churchill-Chu | Correlating Equations for Laminar and Turbulent Free Convection from a Horizontal Cylinder. | International Journal Heat Mass Transfer (1975) 18, 1049-1053. |

| 5 | Fancher, & Brown, G.G. | Prediction of Pressure Gradients for Multiphase Flow in Tubing. | SPE Journal (Mar. 1963), 59-64. |

| 6 | Fortunati | Two Phase Flow Through Well-head Chokes. | SPE 3742 1972 SPE European Spring Meeting, Amsterdam, May 17-18. |

| 7 | Hagedorn, A.R. & Brown, K.E. | Experimental Study of Pressure Gradients Occurring During Continuous Two-Phase Flow in Small-Diameter Vertical Conduits. | JPT (Apr. 1965), 475-484. |

| 8 | Mandhane et al | A Flow Pattern Map for Gas-liquid Flow in Horizontal Pipes. | International Journal Multiphase Flow, 1, 537-541. |

| 9 | Moody | Friction Factor for Pipe Flow. | Trans., AIME (1944), 66, 671-675. |

| 10 | Mukherjee, H. & Brill, J.P. | Liquid Holdup Correlations for Inclined Two-Phase Flow. | JPT (May 1983), 1003-1008. |

| 11 | Oranje | Condensate Behaviour in Gas Pipeline is Predictable. | Oil and Gas Journal (July 1973), 39-43. |

| 12 | Orkiszewski | Predicting Two Phase Pressure Drop in Vertical Pipes. | JPT (June 1967), 829-833. |

| 13 | Duns, H. Jr & Ros, N.C.J. | Vertical Flow of Gas and Liquid Mixtures in Wells. | Proc., Sixth World Petroleum Congress, Frankfurt (1963) 451. |

| 14 | Tansev, E. Startzman, R. & Cooper, A. | Predicting Pressure Loss and Heat Transfer in Geothermal Wellbores. | SPE 5584 1975 SPE Annual Fall Meeting, Dallas, Sept. 28-Oct. 1. |

| 15 | Gould, T.L, Tek, M.R. & Katz, D.L. | Two-Phase Flow Through Vertical, Inclined, or Curved Pipe. | JPT, August, 1974, 915-925. |

Reference: PROSPER Use’s Guide.