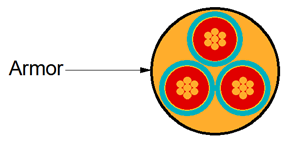

As per API RP11S5, cable armor is the outer covering of the cable which provides mechanical protection during installation and removal of cables. In addition to mechanical protection, the armor provides mechanical constraint against swelling and expansion of underlying elastomeric materials in case of any exposure to well fluids.

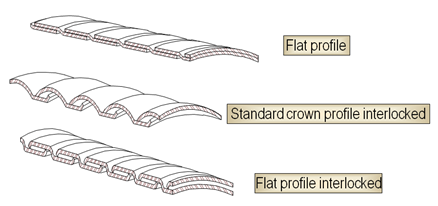

Armor profile types:

There are different armor profile types, it could be flat, interlocked or flat interlocked as per the graph below. Flat armor is used where the overall thickness of the cable is restricted. In the other hand, interlocked armor is used to minimize the tendency of the armor to unravel. Actually, it is less likely to snag during running and pulling.

Metallurgy:

Armor material usually consists of galvanized steel. For severe applications, stainless steel or Monel is used. Monel can be used to resist to the most corrosive conditions. Stainless steel armor, although it is not as effective as Monel it presents a lower-cost alternative.

- Galvanized steel: is constructed from mild steel (low-carbon steel) that has been zinc-coated on all sides. Although most well conditions permit the use of galvanized steel metallurgy, it is susceptible to corrosion in the presence of sour gases (H2S and CO2), strong acid jobs application…

- Stainless Steel: is a class of steels containing significant quantity of chromium, in conjunction with other alloys. In ESP cable application, the most used grades of stainless steel are 316 and 409. A special attention should be paid in application where chloride ions are present; actually pitting and Stress Corrosion Cracking may occur in stainless steels.

- Monel: is a metal alloy with a greater than 60% nickel, 2% manganese, less than 4% iron, and the reminder copper. It may be an expensive armor material and it is generally selected for the most severe environment (H2S, CO2 and high temperature).