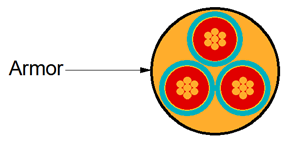

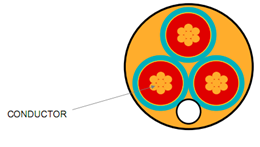

As per API RP11S5, cable armor is the outer covering of the cable which provides mechanical protection during installation and removal of cables. In addition to mechanical protection, the armor provides mechanical constraint against swelling and expansion of underlying elastomeric materials in case of any exposure to well fluids.