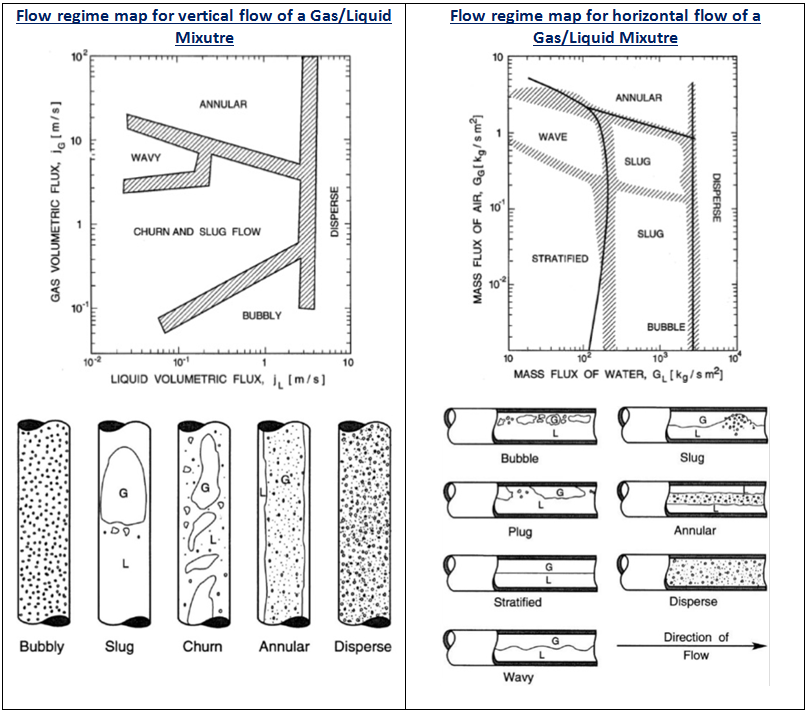

Flow Regime maps are useful tools for getting an overview over which flow regimes we can expect for a particular set of input data. Each map is not, however, general enough to be valid for other data sets. It gives a description of the geometrical distribution of a multiphase fluid moving through a pipe. Different flow regimes are used to describe this distribution, the distinction between each one being qualitative and somewhat arbitrary. In vertical or moderately deviated pipes, the most common flow regimes for gas-liquid mixtures are bubble flow, slug flow, mist flow, churn flow and annular flow. In horizontal wells, there may be stratified or wavy stratified flow in addition to many of the regimes observed in vertical wells. Two-phase flow regimes have often been presented as plots, or maps, with the phase velocities or functions of them on each axis. Earlier maps were named after their authors, for example Griffith-Wallis, Duns-Ros and Taitel-Dukler. The following Figures give an example of flow regime map for a vertical and horizontal flow of a Gas/Liquid mixture.