In 1968, Vogel established an empirical relationship ( Vogel’s inflow performance relationship )for flowrate prediction of a solution gas-drive reservoir in terms of the wellbore pressure based on reservoir simulation results.

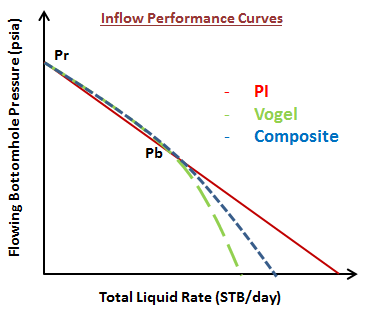

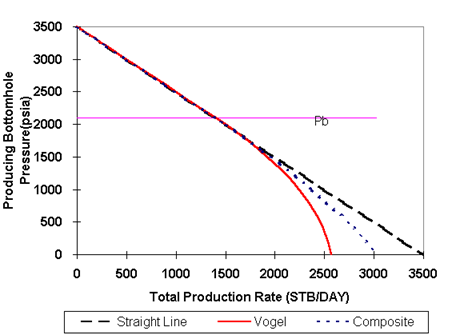

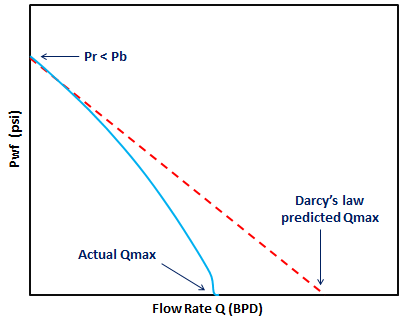

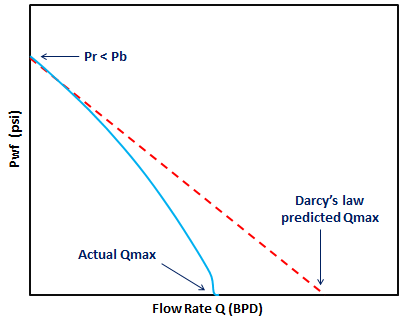

Vogel’s Model compared to PI Model…

The PI model works very well for single phase fluid (water, oil, or water/oil) flowing into a wellbore, even though water and oil are two separate phases, they are considered as a single phase since they are both liquid.

But what happens when gas comes out of solution?

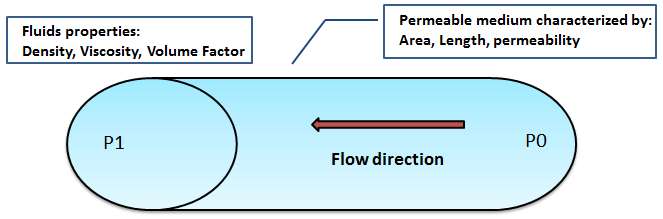

” The flow velocity of a fluid in a porous medium is inversely proportional to the fluid viscosity. Typically, gas viscosity in the reservoir is about fifty times smaller than for liquid oil and consequently, the gas flow velocity is much greater. As a result, it is normal, when producing from a reservoir in which there is a free gas saturation, that gas will be produced in disproportionate amounts in comparison to the oil “. (Dake, fundamentals of reservoir engineering).

Compared to liquid, gas has much higher permeability and much lower viscosity. These two factors will give the gas a much higher flow rate than liquid inside the reservoir, so that:

QG >> QL

Below the bubble point pressure, the solution gas escapes from the oil and become free gas. The free gas occupies some portion of pore space and reduces flow of oil. This effect is quantified by:

- A decrease of oil Relative permeability

- An increase of oil viscosity (as its solution gas content drops)

Therefore, the combination of the relative permeability effect and the viscosity effect results in lower oil production rate at a given bottom-hole pressure.

Graphically, it would looks like this:

Continue reading →