Junction box, Check and Drain Valves, Downhole Sensor and Centralizers are some kinds of ESP Accessory Equipment. These type of equipment could play an important role to operate the ESP efficiently and maximize it run lifetime.

Junction Box:

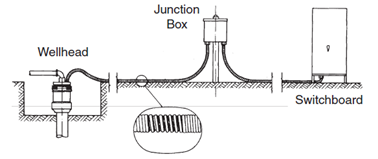

The power cable coming from the well is connected to a surface electric cable leading to the switchboard. As seen in the figure below, the two cables are joined in the junction box, also called a “vent box”. The surface cable connects the junction box to the motor control panel and the motor control panel to the secondary side of the transformers.

It is a ventilated, weatherproof box performing the following three important functions:

- Provides the electrical connection between the downhole and the surface electric cable.

- Vents any gas to the atmosphere which might reach this point due to migration of well gases up the ESP power cable. The venting of gas eliminates the danger of fire or explosion that could happen if gases travel in the cable to the switchboard.

- Acts as an easily accessible test point for electric checks of the downhole equipment.