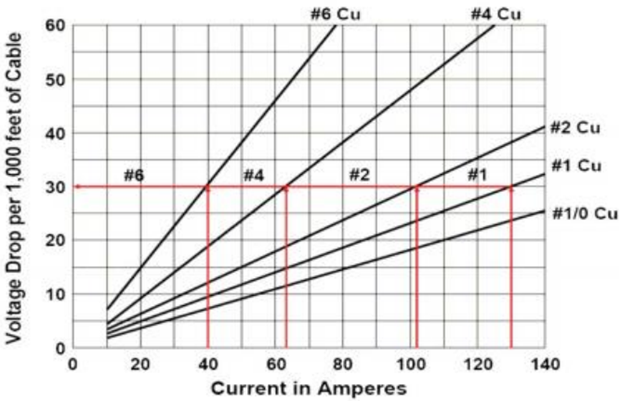

Cable power losses or power drop are due to the conductor resistance heating that occurs when current flows. These cable losses are more often called KW losses or I²R losses. This is expressed by the following formula:

Power losses = 3 × (I²R) /1000

Where: Power losses in kW units, I is the current (in amps) and R (in ohms) is the average conductor resistance.

How to lower the resistance in the cable?

Power lost in a cable depends on the cable length, cable size and the current through the cable. Therefore, there are three ways to lower the resistance in the cable:

- Shorten the length of the cable,

- Increase the size of the conductor,

- Decrease the current through the cable.