Pump Theory:

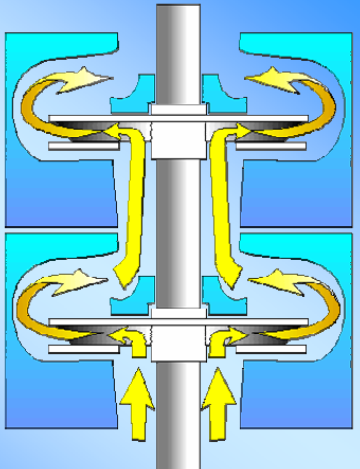

The term “centrifugal pump” has been used to describe a wide variety of pumping applications and designs throughout the years. A Centrifugal Pump is a machine that moves fluid by spinning it with a rotating impeller in a diffuser that has a central inlet and a tangential outlet. The path of the fluid is an increasing spiral from the inlet at the center to the outlet tangent to the diffuser. The fluid rotational motion is the result of the concept of centrifugal forces.

The pressure (head) develops against the inside wall of the diffuser because of the curved wall forces fluid to move in a circular path.

Centrifugal Pump:

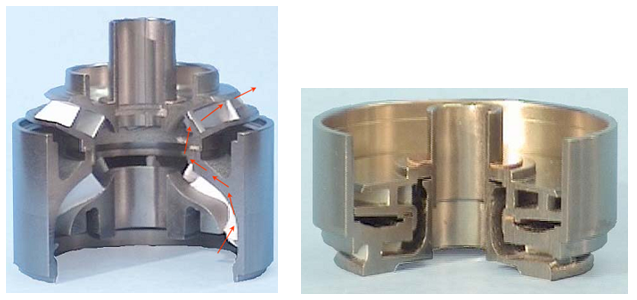

The centrifugal pump is a multi-stage pump, containing a selected number of impellers equipped with vanes, inside a closely fitted diffuser, located in series on an axial shaft, driven by the electrical motor. It creates pressure by the rotation of a series of vanes in an impeller. The motion of the impeller forms a partial vacuum at the suction end of the impeller.

The impeller’s job is to transfer energy by rotation to the liquid passing through it, thus raising the kinetic energy. The diffuser section then converts this energy to potential energy, raising the discharge pressure.

Outside forces, such as the atmospheric pressure or weight of a column of liquids, push fluid into the impeller eye and out to the periphery of the impeller. From there, the rotation of the high-speed impeller throws the liquid into the diffuser.

Each “pump stage” consists of an impeller and a diffuser. Again, the impeller takes the fluid and imparts kinetic energy to it. The diffuser converts this kinetic energy into potential energy (head).

Overall, the pumps’ main function is to lift fluid from one level to another.

You May Also Like…

- Submersible Pump System Overview

- Pump Intake

- Motor Seal

- ESP Motor

- ESP Cable

- ESP Motor Switchboard

- Variable Frequency Drive Basics

- Introduction to transformer: How it works?

- Wellhead Equipment for ESP

- ESP Accessory Equipment