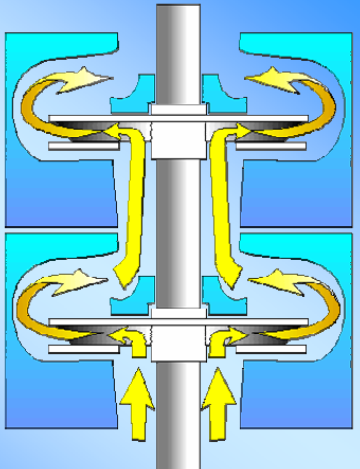

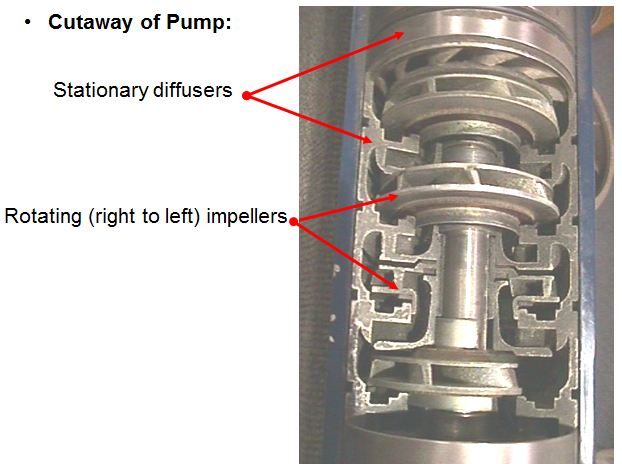

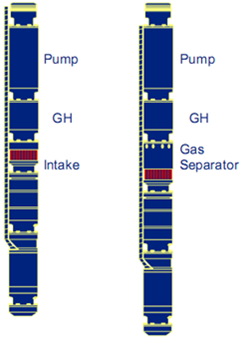

Gas handling devices may be a better alternative for wells prone to high free gas, slugging, foams and emulsions. These are essentially centrifugal pumps with large stages, mixed (or axial) impellers, large vane openings, steep vane exit angles and sometimes include multiple vanes.

Instead of separating, their purpose is to break large gas bubble into smaller ones thereby reducing the risk of gas locking and making it easier for gas to be re-absorbed into solution, and to homogenize the gas with liquid phases, prior to entering the pump intake.

An additional benefit of gas handlers is, because more gas is retained in the flow stream, this gas is then available to help lift fluids in the tubing above the ESP discharge head thereby reducing hydraulic horsepower requirements.

Applications: A Gas Handler is generally considered if the Free Gas Percentage at the intake of the pump is from 30% to 60% by volume.