| Capital cost |

· Relatively low capital cost if electric power available.

· Costs increase as horsepower increases. |

| Downhole equipment |

· Requires proper cable in addition to motor, pumps, seals, etc.

· Good design plus good operating practices are essential. |

|

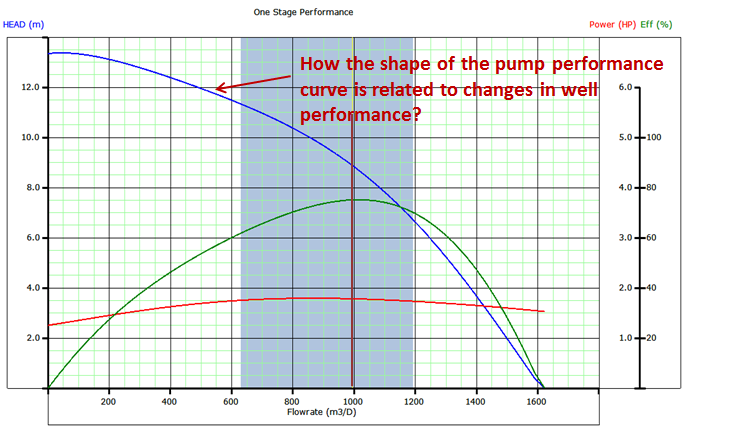

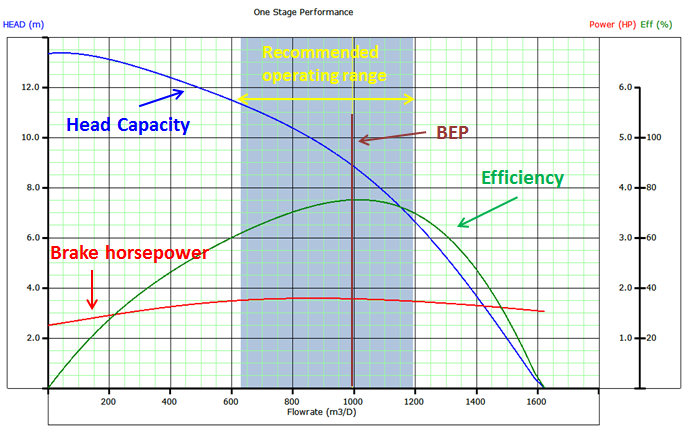

Operating efficiency

(Hydraulic HP/Input HP) |

· Good for high rate wells but decreases significantly for < 1000 BFPD.

· Typically total system efficiency is about 50% for high rate wells but for < 1000 BPD, efficiency typically <40%.

· Can be as high as 60% for large ID equipment. |

| Flexibility |

· Poor for fixed speed.

· Requires careful design.

· VSD provides better flexibility. |

| Miscellaneous problems |

· Requires a highly reliable electric power system.

· System very sensitive to changes downhole or in fluid properties. |

| Operating costs |

· Varies.

· If high HP, high energy costs.

· High pulling costs result from short run life especially in offshore operation.

· Repair costs often high. |

| System reliability |

· Varies.

· Excellent for ideal lift cases.

· Poor for problem areas (very sensitive to operating temperatures and electrical malfunctions). |

| Salvage value |

· Fair.

· Some trade in value.

· Poor open market values. |

| System (Total) |

· Fairly simple to design but requires good rate data.

· System not forgiving.

· Requires excellent operating practices.

· Follow API RP’s in design, testing, and operation.

· Each well is an individual producer using a common electric system. |

| Usage/outlook |

· An excellent high rate artificial lift system.

· Best suited for <200 0F and >1000 BFPD rates.

· Most often used on high water cut wells.

· Used on about 5% of US lifted wells. |

| Casing size limits

(Restricts tubing size) |

· Casing size will limit use of large motors and pumps.

· Avoid 4.5” casing and smaller.

· Reduced performance inside 5.5” casing depending on depth and rate. |

| Depth limits |

· Usually limited to motor HP or temperature.

· Practical depth about 10,000 feet.

· 1000’ – 10000’ TVD is typical, Max is 15,000 ‘ TVD. |

| Intake capabilities

(Ability to pump with low pressures at pump intake) |

· Fair if little free gas (i.e. >250 PSI pump intake pressure).

· Poor if F = 666*(Qg/Ql)/Pip > 1.0

Where: Pip: intake psi; Qg: gas vol; Ql: liquid vol @ intake conditions.

· 5% gas at low pressures can cause problems. |

| Noise level |

· Excellent.

· Very low noise.

· Often preferred in urban areas if production rate high. |

| Obtrusiveness |

· Good.

· Low profile but requires transformer bank. |

| Prime mover flexibility |

· Fair.

· Requires a good power source without spikes or interruptions.

· Higher voltages can reduce losses. |

| Surveillance |

· Fair.

· Electrical checks but special equipment needed otherwise. |

| Relative ease of well testing |

· Good.

· Simple with few problems.

· High water cut and high rate wells may require a free water knock out (three-phase separator). |

| Time cycle and pump off controllers application |

· Poor.

· Soft start and improved seal/ protectors recommended. |

| Corrosion/scale handling ability |

· Fair.

· Batch treating inhibitor only to intake unless shroud is used. |

| Crooked/deviated holes |

· Good.

· Few problems.

· Limited experience in horizontal wells.

· Requires long radius wellbore bends to get through.

10° typical,

0 – 90° < 10° / 100 build angle maximum.

· However must set in section 0 – 2° max deviation. |

| Duals application |

· No known installations.

· Larger casing required.

· Possible run & pull problems. |

| Gas handling ability |

· Poor for free gas (i.e. >5% through pump).

· Poor if F = 666 * (Qg/Ql)/Pip > 1.0

Where: Pip: intake psi; Qg: gas vol; Ql: liquid vol, @ intake conditions.

· Rotary gas separators helpful if solids not produced. |

| Offshore application |

· Good.

· Must provide electrical power and service pulling unit. |

| Paraffin handling capability |

· Fair.

· Hot water/oil treatments, mechanical cutting, batch inhibition possible. |

| Slim hole completions

(2 7/8″ tubing, casing) |

· No known installations. |

| Solids/sand handling ability |

· Poor.

· Requires <100 – 200 PPM solids for standard construction.

· 200 – 2000 ppm possible with special bushings, stage materials, coatings, and thrust supporting bearings or fixed pumps employed.

· A maximum of about 5000 ppm might be possible depending on pump and sharpness and angularity of sand. |

| Temperature limitation |

· Limited to <2500F for standard & <4000F for special motors & cable.

· 100 – 275°F typical. |

| High viscosity fluid handling capability |

· Fair.

· Limited to as high as 1000 cp.

· Depends on economics. (~>7-9°API)

· Increases HP and reduces head.

· Potential solution is to use “core flow” with 20% water. |

| High volume lift capabilities |

· Excellent.

· Limited by needed HP and can be restricted by casing size.

· In 5.5” casing can produce 4000 BFPD from 4000 feet W/240 HP.

· Tandem motors increase HP & operating costs.

200 – 20,000 bpd typical, ~30,000 bpd max.

52,000 bpd, shallow, 10.25” equip has been done. |

| Low volume lift capabilities |

· Generally poor.

· Lower efficiencies and high operating costs <400 BFPD.

|